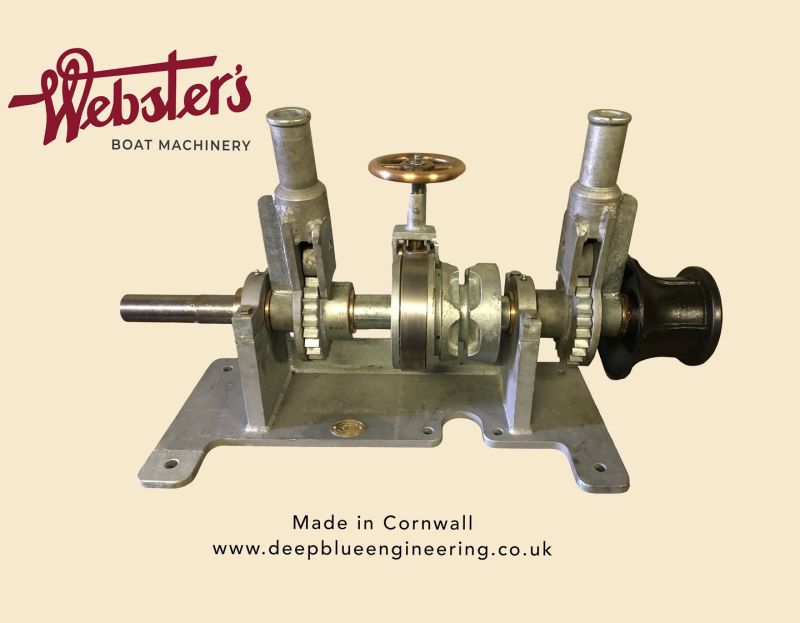

The No.50 windlass is modelled on the original old ratchet windlass made by Lunenburg Foundry in Nova Scotia for so many years. We restored one of the originals some years ago and sadly when we enquired about purchasing new parts, the foundry told us that they no longer made their windlasses. After some consideration, we took the decision to make the parts we needed in-house, but also to record all of the dimensions of the good parts so that we could make these windlasses in the future if a customer ever needed one. In addition to the No.50, although the smaller windlasses are of a completely different design, this did provide inspiration for our other ratchet windlass designs: the model No.20 No.25 and No.30.

The No.50 can be supplied with a wide range of specifications, from a basic two ratchets, brake, cain gypsy and warping drum, through to a windlass with two gypsies, two warping drums with dog clutches to facilitate independent operating of each warping drum and gypsy, and two brake assemblies. It can also be supplied with a power function: the model No.51, which is covered in this website. Although we can provide a windlass with a standard set of dimensions, these windlasses tend to be made to order and therefore made to fit a specific vessel.

The No.50 is a manually operated windlass, suitable for vessels up to 65 tonnes displacement.

The No.50 can be supplied as a powered windlass, with the motor and gearbox positioned below deck and a dog clutch, as a means for selecting manual or powered operating, incorporated into the main shaft arrangement on deck.

For more information, including technical data and downloads, click on the relevant section heading at the bottom of the page.